Email:

sales@hypersolidmetal.comWhatsapp:

8618625975081

Email:

sales@hypersolidmetal.comWhatsapp:

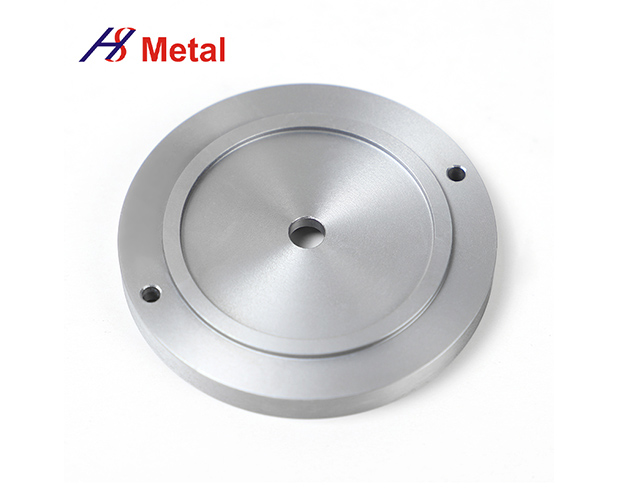

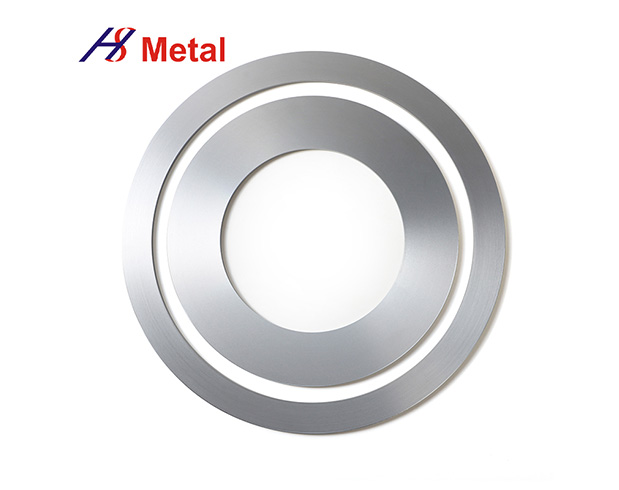

8618625975081Tungsten alloy discs are primarily composed of tungsten, combined with other metal elements such as nickel and iron through a specific process. One of the most significant characteristics of tungsten alloy discs is their high specific gravity. Their density typically ranges from 16.5 to 18.75 g/cm³, significantly superior to common metals.

Tungsten alloy discs exhibit excellent stability in high-temperature environments due to their high melting point and excellent heat resistance. While their melting point can reach around 3400°C, many metals would melt and deform at such high temperatures, but tungsten alloy discs maintain their original physical form and mechanical properties. Tungsten alloy discs possess high strength and hardness, making them resilient in the face of various external forces. Their tensile strength typically reaches 900-1100 MPa, and their hardness is also relatively high, ranging from 25 to 35 HRC. These high strength and hardness make them excellent at resisting wear and impact. Tungsten alloy discs also possess excellent electrical and thermal conductivity, making them a valuable energy transfer tool in electronic devices and heat sinks. Electrical conductivity is a key performance indicator in electronic devices. The excellent electrical conductivity of tungsten alloy discs makes them widely used in the manufacture of electronic devices.

In the aerospace industry, tungsten alloy discs, due to their excellent mechanical, thermal, and chemical properties, are an ideal material for numerous key components, playing a vital role in aircraft, rockets, and other aircraft. In aircraft manufacturing, counterweights play a crucial role in flight stability. Aircraft must maintain a well-balanced state during flight to ensure safety and comfort. Tungsten alloy discs, due to their high specific gravity, are widely used as counterweights in aircraft wings, tails, and fuselages. These counterweights not only effectively adjust the aircraft’s center of gravity but also help maintain stability during high-speed flight, takeoff and landing, and various complex maneuvers.

With the rapid advancement of technology, the electronics and semiconductor industries are constantly evolving, placing increasing demands on material performance. Tungsten alloy discs, with their excellent electrical and thermal conductivity, high melting point, and high strength, have found widespread application in this field, becoming one of the key materials driving advancements in electronic technology. Heat dissipation is a critical issue in electronic devices. As the integration of electronic devices continues to increase, chips and other components generate a lot of heat during operation. If this heat cannot be effectively dissipated, it will lead to a decline in device performance and shortened lifespan. Tungsten alloy’s good thermal conductivity makes it one of the ideal materials for heat dissipation in electronic devices.