Email:

sales@hypersolidmetal.comWhatsapp:

8615038522042

Email:

sales@hypersolidmetal.comWhatsapp:

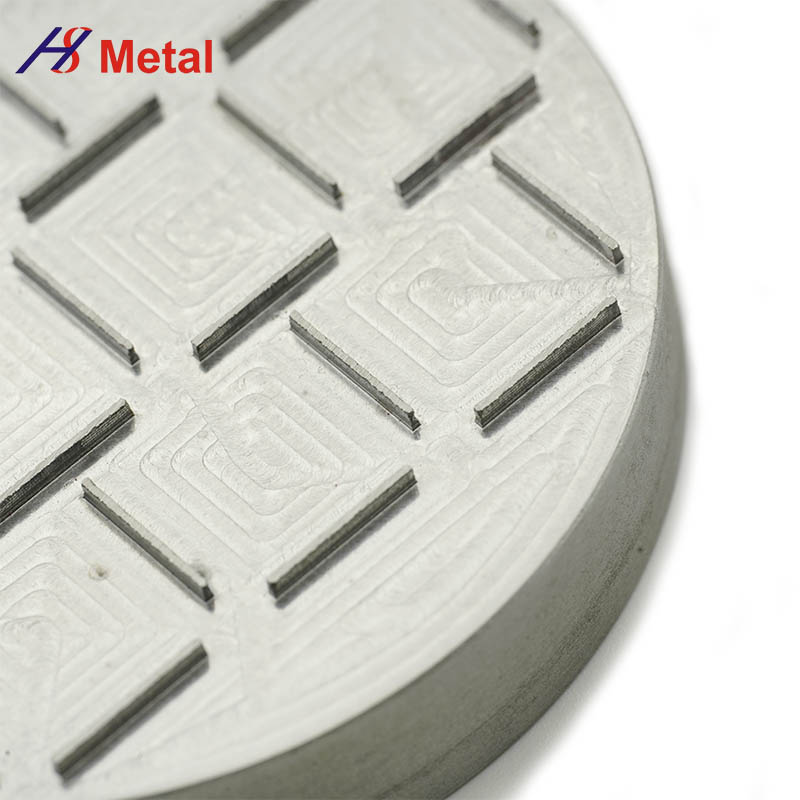

8615038522042A molybdenum wafer is a disc-shaped base made of high-purity metallic molybdenum, typically with a mirror-like surface. In CVD diamond growth equipment, it sits quietly within the vacuum reaction chamber, enduring temperatures approaching 1000 degrees Celsius. This unassuming component provides the initial support for diamond growth.

The diamond growth environment is extremely harsh, and the material properties of the molybdenum wafer perfectly meet this requirement. Its most prominent advantage lies in its extremely high melting point of 2620°C, which allows it to maintain structural stability even at the high temperatures of 800-1200°C required for diamond growth. More importantly, molybdenum and carbon atoms can form a stable molybdenum carbide thin layer on the surface. This property prevents carbon atoms from diffusing further inward and provides an ideal adhesion interface for the diamond nucleus.

In actual production, the molybdenum wafer plays multiple crucial roles. It is the carrier of the diamond seed crystal—fixing carefully selected diamond flakes onto the surface of the molybdenum wafer as a template for crystal growth. Under the influence of microwave plasma, carbon-rich gas decomposes above the molybdenum wafer, and carbon atoms are deposited in an orderly fashion according to the crystal structure of the seed crystal, like layers stacked on a base stone, gradually “growing” a complete diamond crystal.

Simultaneously, the excellent thermal conductivity of the molybdenum wafer ensures a uniform temperature distribution within the growth chamber, which is crucial for obtaining high-quality diamonds. Its coefficient of thermal expansion, similar to that of diamond, protects the diamond from cracking or falling off due to stress during the cooling process after growth.

Today, with advancements in lab-grown diamond technology, the manufacturing process of molybdenum wafers is constantly improving. From purity control to surface smoothness, every improvement contributes to enhancing the quality of lab-grown diamonds.