Email:

sales@hypersolidmetal.comWhatsapp:

8618625975081

Email:

sales@hypersolidmetal.comWhatsapp:

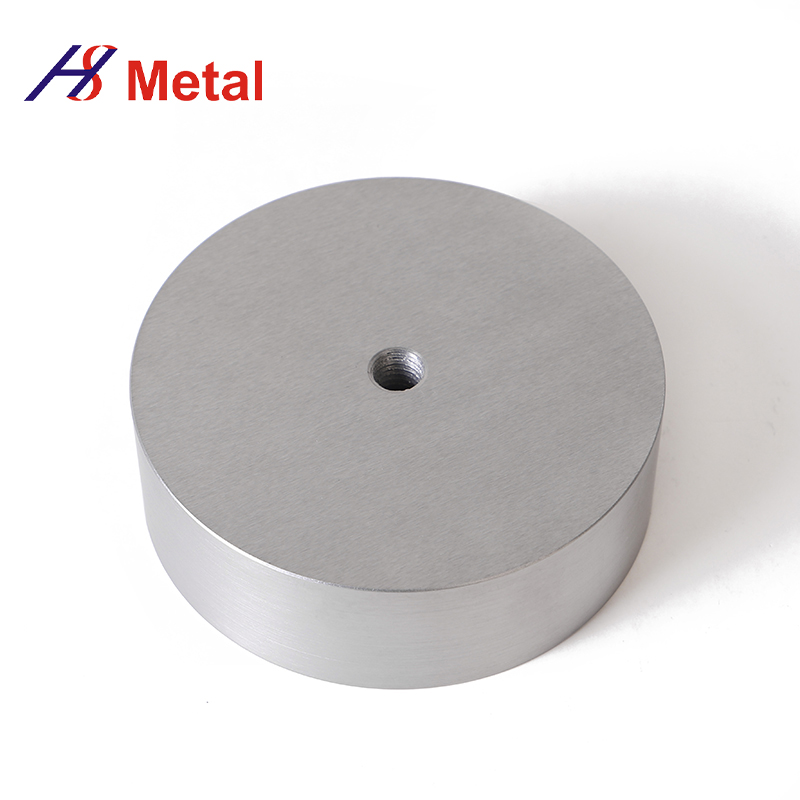

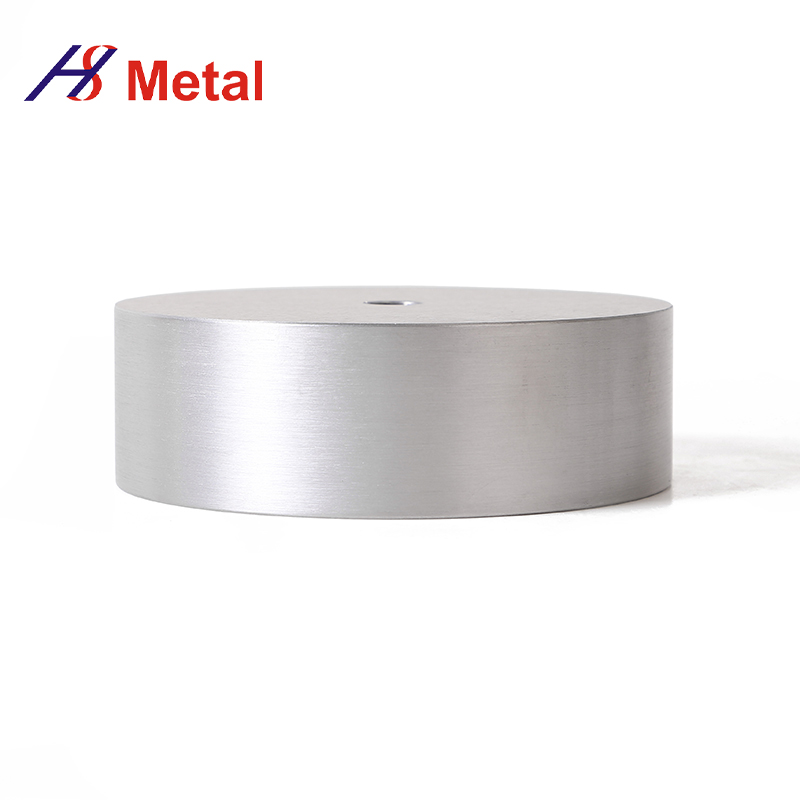

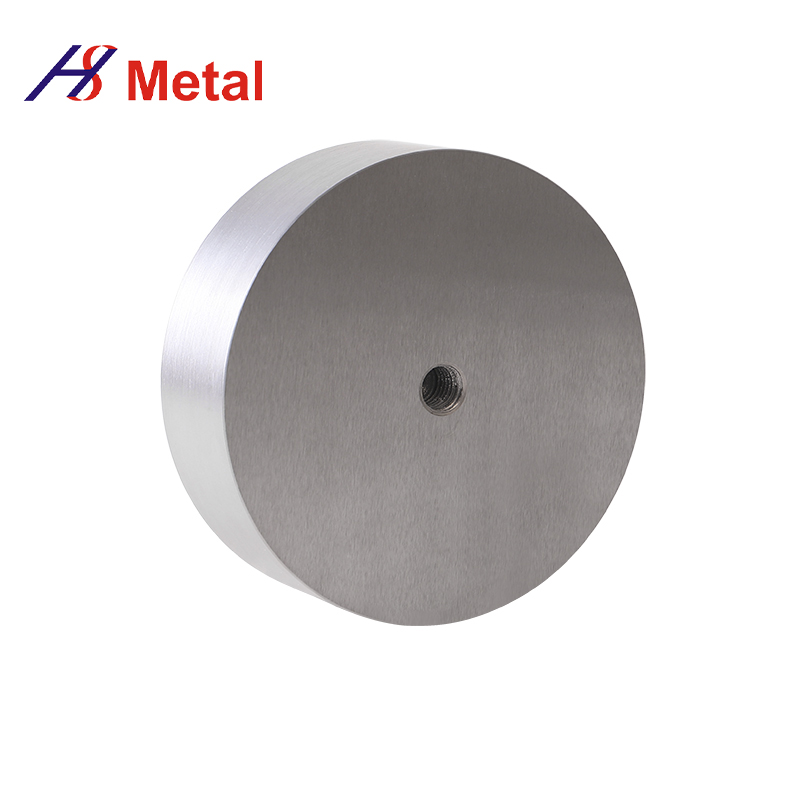

8618625975081High specific gravity tungsten alloy counterweights play a key role in adjusting the center of gravity and balancing the load in many fields due to their high density (usually up to 16.5~19.0g/cm³), good mechanical properties and stability.

1. Aerospace

Engine counterweight: In aircraft turbine engines, counterweights are used to balance high-speed rotating impellers, reduce vibration and noise, and avoid mechanical failures caused by center of gravity offset.

Satellite attitude control: When a spacecraft is in orbit, the center of mass position is adjusted through counterweights, and the propulsion system is used to achieve precise orbit change or attitude stability, such as the counterweight of the solar panel bracket of the Beidou satellite.

Helicopter rotor counterweight: Eliminate the centrifugal force imbalance during rotor rotation, improve flight stability, and reduce fuselage fatigue loss.

2. Marine engineering and shipbuilding

Large cargo ship ballast weight: When the ship is unloaded, the tungsten alloy counterweight is installed at the bottom of the cabin to increase the draft and prevent the hull from tilting due to uneven buoyancy.

Deep-sea detector counterweight: Provide sinking power for underwater robots or submersibles, and control the diving depth and attitude by adjusting the distribution of counterweights.

Offshore drilling platform stability: Counterweights are installed on the pile legs or deck bases of offshore drilling platforms to resist wave impact and wind loads and avoid the risk of the platform capsizing.

3. Industrial machinery and equipment field

Crane boom counterweight: Install a tungsten alloy counterweight at the end of the tower crane’s balance arm to form a moment balance with the boom load to prevent the crane from overturning due to overload.

Punch and forging machine counterweights: offset the inertial force of the slider during high-speed movement, reduce equipment vibration, and improve processing accuracy.

High-speed centrifuge counterweights: in centrifugal separation equipment, the dynamic balance of the drum is adjusted by the counterweight to avoid damage to the instrument due to severe vibration caused by high-speed rotation.

4. Medical and nuclear industry fields

Radiotherapy equipment counterweights: in the treatment head of the linear accelerator, the tungsten alloy counterweight is used to balance the center of gravity of the radiation head to ensure the aiming accuracy of the radiotherapy beam.

Nuclear reactor pressure vessel counterweights: as a fixed counterweight of the pressure vessel, the radiation shielding properties of tungsten alloy are used to assist in blocking neutron radiation.

5. Sports and high-end consumer goods

Tungsten alloy weights are embedded in the bottom of the club head to adjust the sweet spot position, improve the energy transfer efficiency when hitting the ball, and increase the distance and direction of the ball.

Micro tungsten alloy weights are used in the balance wheel of some mechanical watches. The swing frequency of the balance wheel is calibrated by adjusting the position of the weights to improve the accuracy of travel time.

6. Other special scenarios

Tungsten alloy weights are used in the pendulum system of the seismometer to increase the mass of the pendulum and improve the sensitivity and stability of seismic wave detection.

Racing cars adjust the front and rear axle load distribution (such as the chassis weight of F1 racing cars) by installing tungsten alloy weights at specific positions on the chassis or body to optimize the handling performance; the engine compartment weights of some luxury cars are used to reduce vibration noise.