Email:

sales@hypersolidmetal.comWhatsapp:

8613592098266

Email:

sales@hypersolidmetal.comWhatsapp:

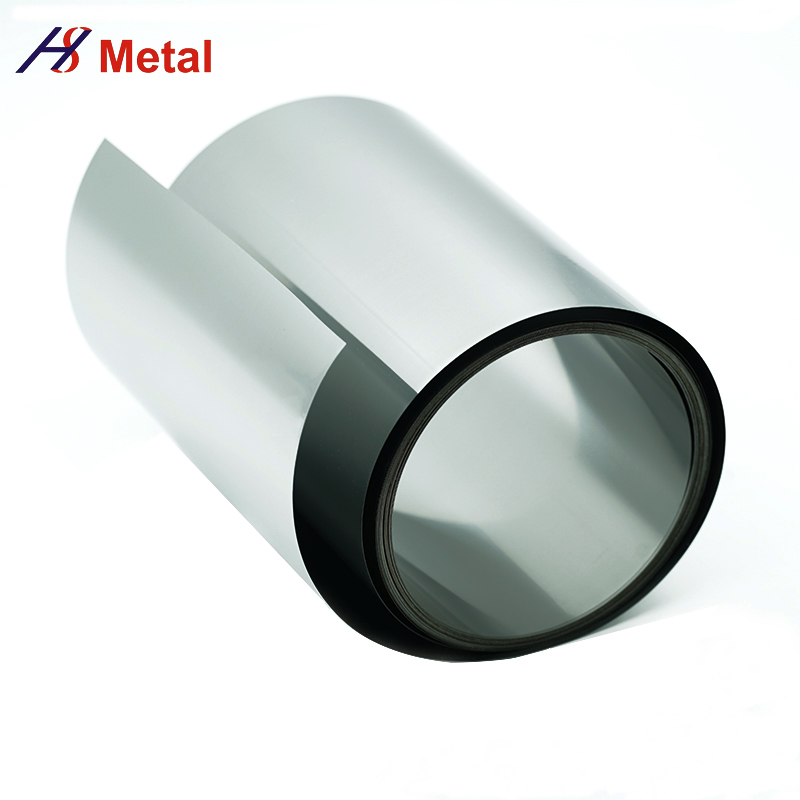

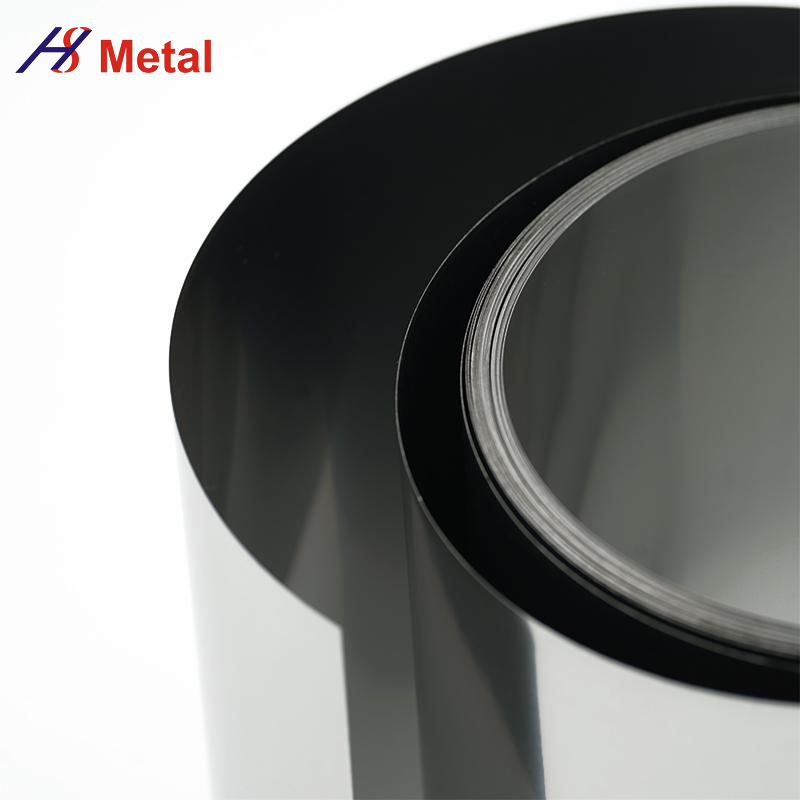

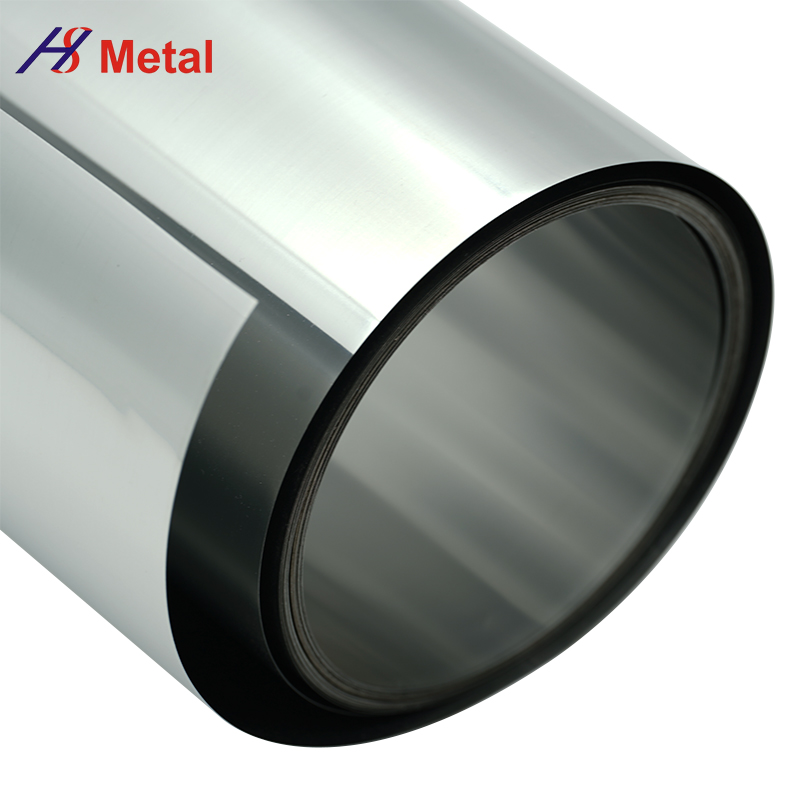

8613592098266Like molybdenum plates, rods and wires, molybdenum foil is also a typical molybdenum product. It is a thin sheet composed of transition metal molybdenum (Mo) and rare earth elements. Its English name is Molybdenum foil. Its purity is usually greater than 99.95%, with a thickness of 0.025-0.09mm, a width of 30-100mm, and a length greater than 200mm. The surface conditions include alkaline pickling surface, annealing state and polished surface.

In terms of physical and chemical properties, molybdenum foil is a silver-gray metal sheet with a metallic luster. It has a melting point of approximately 2620°C, a boiling point of approximately 5560°C, and a relative density of 10.2 g/cm³. It exhibits high hardness, low thermal expansion coefficient, high thermal conductivity, low resistivity, and excellent chemical stability and electrochemical properties. At room temperature and pressure, it does not react with air or water, but it slowly oxidizes under heating.

In terms of production methods, the following steps are involved: Medium-particle molybdenum powder is used as the raw material, and cold isostatic pressing is used to produce a molybdenum compact. This is followed by composite sintering, low-temperature, high-deformation blanking, low-temperature cross-hot rolling, alkali cleaning, grinding, and shearing. Finally, warm rolling, hydrogen annealing, surface cleaning and shearing, cross-cold rolling, surface degreasing, and finally vacuum stress relief annealing, cutting, and inspection to obtain the desired product.

In terms of usage, molybdenum foil is widely used in the production of interconnection lines and composite gates of electronic devices, reflective screens and cover plates in sapphire crystal growth furnaces, heating belts and connectors in vacuum furnaces, sputtering targets for plasma coating, high-temperature resistant boats and other products.