Email:

sales@hypersolidmetal.comWhatsapp:

8618625975081

Email:

sales@hypersolidmetal.comWhatsapp:

8618625975081Molybdenum components are critical to the operation of high-power X-ray tubes used in computer axial tomography (CAT, or CT) equipment. The vacuum tube that produces X-rays is similar in many ways to the vacuum tubes used in earlier electronic devices, but it must withstand much more severe thermal and stress environments. The electrons in the X-ray tube do not transmit signals as in the tube, but instead inject their energy into the target, thereby producing X-rays. The process itself is not very efficient, but high currents and high accelerating voltages increase the number of X-rays produced. Most of the electron beam energy produces heat rather than X-rays, so the target material must be able to withstand very high temperatures. The cathode assembly is a machined component from molybdenum rolled product, and the component must be able to withstand the thermal loads imposed by the internal filament. The rotor is also machined from molybdenum or molybdenum alloy Mo-TZM round bar because it can withstand the rotational load of the large target material and conduct and dissipate heat to the target. High temperature strength is also extremely important for this component. The target is perhaps the most important part of an X-ray tube, as it must withstand extremely high temperatures, high thermal stresses, and mechanical stresses from the centrifugal forces of the rotating target, which can rotate at speeds up to 10,000 RPM. The target is typically made of a molybdenum alloy, Mo-TZM, or a proprietary carbide-reinforced alloy similar to TZM to withstand these stresses. Its outer surface contains an integral track made of a tungsten-rhenium alloy that can exceed 70% of its melting temperature during operation. The target and track are manufactured as a single component, powder pressed in a steel mold and sintered to densify the target and bond the tungsten-rhenium alloy track to the molybdenum alloy Mo-TZM matrix. The sintered target is then hot forged to densify it slightly and increase its strength, machined to final dimensions, and brazed to a carbon heat sink, the purpose of which is to store the heat generated by the X-ray tube during operation and dissipate it in a controlled manner.

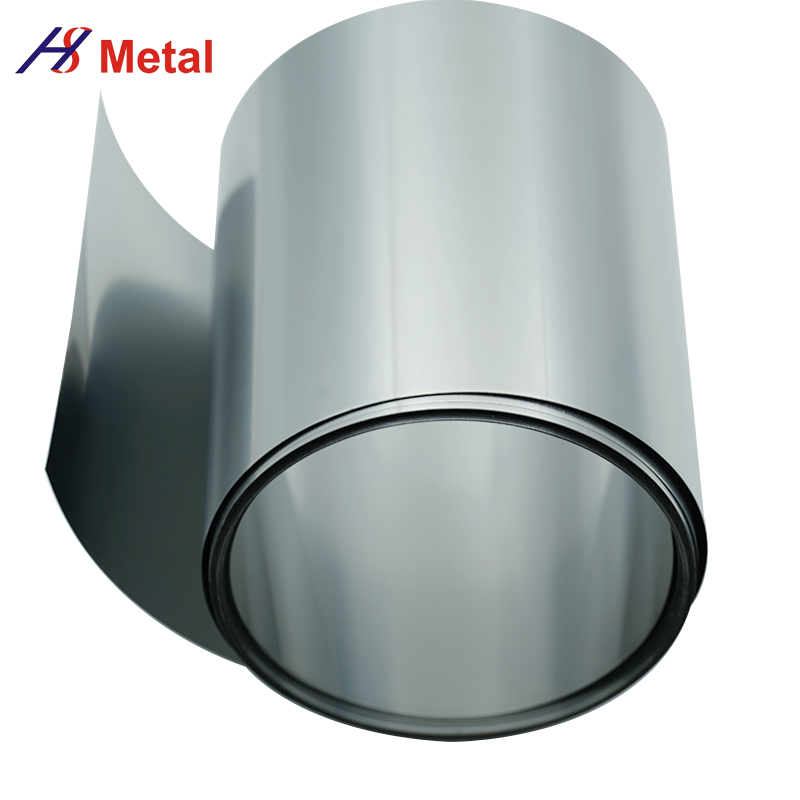

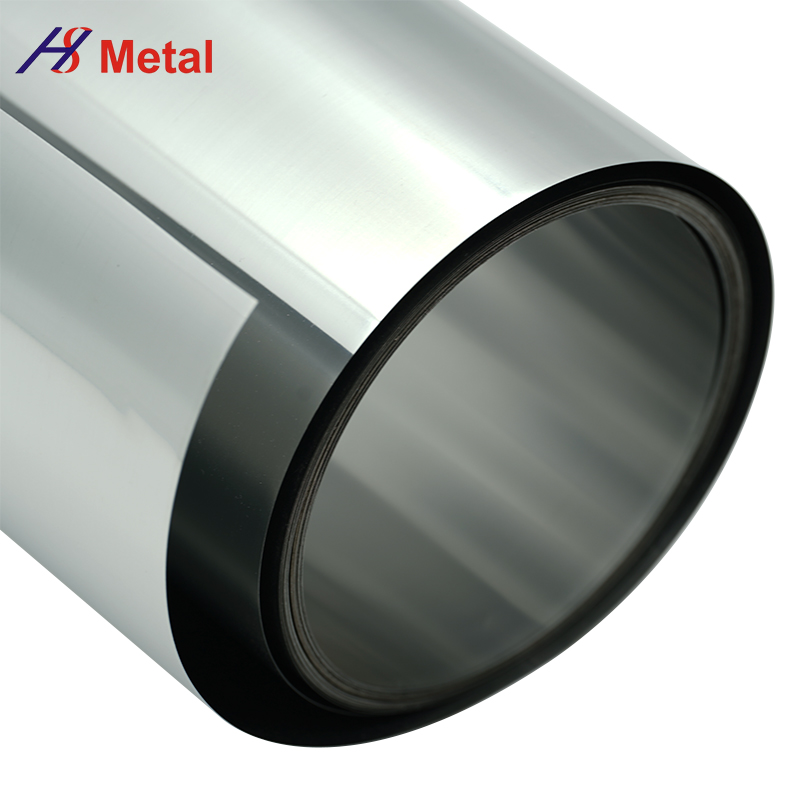

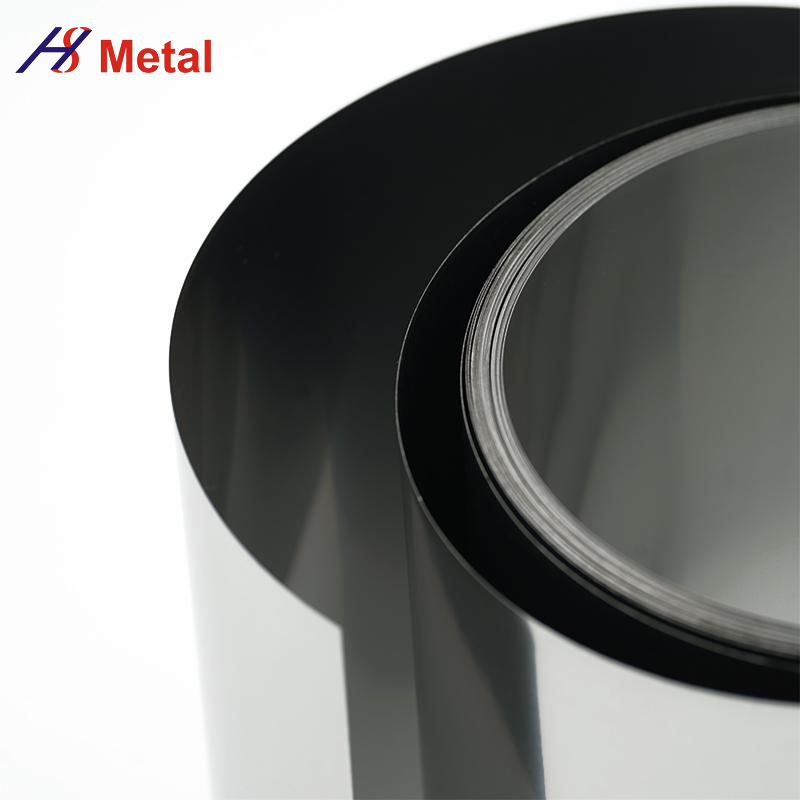

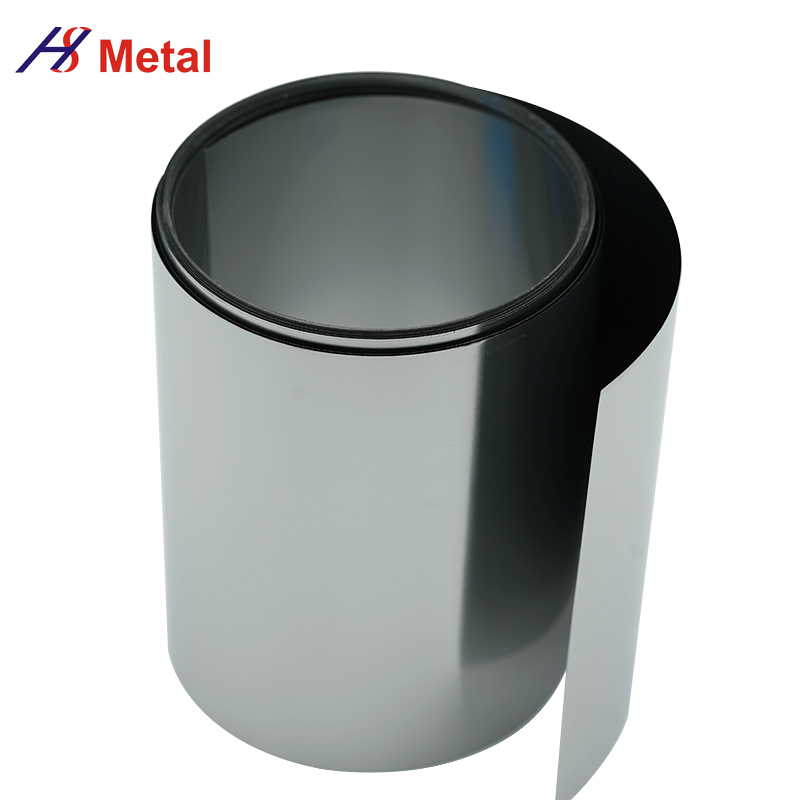

Molybdenum foil is also important in the detector array that captures the X-ray signal for analysis. The detectors are separate units, using molybdenum foil as collimators (to separate the detectors from each other). Molybdenum is used because it has a high modulus of elasticity to resist bending under centrifugal loads during operation, and it effectively shields adjacent detectors from errant radiation. The sheet thickness tolerances are extremely tight so that the entire detector array remains within overall dimensional tolerances and there is no tolerance “stack-up” that degrades image quality.