Email:

sales@hypersolidmetal.comWhatsapp:

8618625975081

Email:

sales@hypersolidmetal.comWhatsapp:

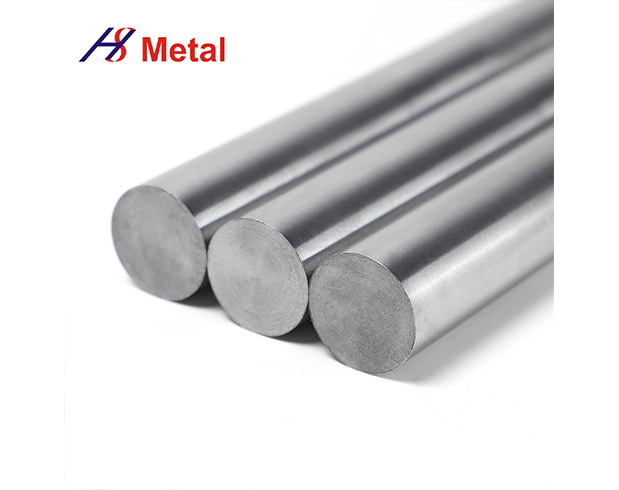

8618625975081The first application of molybdenum metal – wires in incandescent lamps – dates to the early 1900s. Molybdenum was chosen due to its stability and strength at high temperatures. Since this first application, scientists and engineers have discovered that molybdenum has other properties that make it a material of choice for many applications. Some of these take advantage of molybdenum’s strength and stability at high temperatures, as in the first filaments. However, molybdenum has many other properties that make it attractive for applications beyond traditional high-temperature components, including:

· High thermal conductivity

· High electrical conductivity

· Low coefficient of thermal expansion

· Resistance to corrosion by molten metals

· Compatible with most glass compositions

· Resistance to thermal shock

· High hardness

· Strong bond to glass used in lamps and electronic devices

Because of its many properties, molybdenum metal and its alloys are attractive to engineers and designers, molybdenum metal and its alloys are often used in:

· Lighting fixtures

· Electrical and electronic equipment

· Medical equipment

· Materials processing equipment

· High-temperature furnaces and related equipment

· Thermal spray coatings

· Components for the aerospace and defense industries

All of these applications require a unique combination of properties. Molybdenum and its alloys, as well as molybdenum metal composites, offer a unique combination of thermal conductivity, electrical conductivity, thermal expansion properties, high-temperature strength and creep resistance, vapor pressure, environmental stability, and wear resistance, making them ideal choices.