Email:

sales@hypersolidmetal.comWhatsapp:

8618625975081

Email:

sales@hypersolidmetal.comWhatsapp:

8618625975081Tungsten wire for glass heating is a tungsten metal wire used for heating in glass processing or manufacturing. Tungsten has an extremely high melting point (about 3422°C) and good high temperature stability, making it an ideal heating element for high temperature environments. In the glass industry, tungsten wire is often used in precision equipment such as glass fiber drawing furnaces, glass tube production equipment or laboratory glass processing equipment.

1. Material properties of tungsten wire

1.1 Ultra-high melting point

Tungsten wire is made of high-purity tungsten, and the melting point of tungsten is as high as 3422°C, which can work stably in extremely high temperature environments.

1.2 Excellent thermal stability

At high temperatures, tungsten wire can still maintain good mechanical strength and structural integrity, and is not easy to deform or break.

1.3 Corrosion resistance

Tungsten has good corrosion resistance to a variety of chemicals and is suitable for use in complex industrial environments.

1.4 Low thermal expansion coefficient

Tungsten has a low thermal expansion coefficient, which is more compatible with the thermal expansion characteristics of glass materials, effectively reducing cracking or deformation caused by thermal stress during heating.

2. Main applications of tungsten wire for glass heating

2.1 Glass melting

In the glass production process, tungsten wire is used as an electric heating element to heat and melt glass raw materials to ensure that the raw materials are fully melted and reach a uniform liquid state. Its high temperature performance ensures that the glass melting furnace can maintain a stable high temperature environment and improve production efficiency.

2.2 Glass molding

In processes such as glass tube drawing, blowing or pressing, tungsten wire is used for local heating to keep the glass in an appropriate softening state for easy shaping.

2.3 Laboratory and precision processing

In laboratories or small glass processing equipment, tungsten wire is often used for thermal processing of glassware, such as cutting, sealing or molding. Its precise heating capacity meets the production needs of high-precision glass products.

2.4 Applications in special environments

Since tungsten easily reacts with oxygen at high temperatures, tungsten wire is usually used in a vacuum or inert gas (such as argon or nitrogen) environment to prevent oxidation and extend service life.

3. Advantages of tungsten wire in glass processing

3.1 High temperature tolerance

Tungsten wire can withstand temperatures far exceeding other metals and is suitable for high temperature processes required for glass melting and molding.

3.2 Efficient heat conduction

Tungsten wire heats quickly and has uniform temperature distribution, which helps improve the accuracy and consistency of glass processing.

3.3 Long life

Under appropriate conditions (such as vacuum or inert gas protection), tungsten wire has a long service life and reduces maintenance costs.

3.4 Compatibility with glass

The low thermal expansion coefficient of tungsten is similar to the thermal expansion characteristics of glass materials, which reduces stress problems caused by thermal expansion and contraction, thereby reducing the defect rate of glass products.

4. Form and design of tungsten wire

According to specific industrial needs, tungsten wire can be made into different forms to meet the design requirements of heating equipment:

4.1 Single strand tungsten wire

Suitable for small or precision heating devices, providing local point heating.

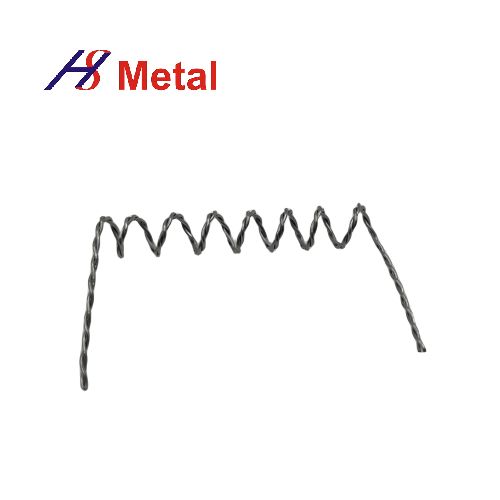

4.2 Twisted tungsten wire

Made by twisting multiple strands of tungsten wire, it has enhanced mechanical strength and is suitable for large-area heating.

4.3 Braided tungsten mesh

Used for large equipment that requires uniform heating, such as heating components of glass melting furnaces.

In addition, the diameter, length and other specifications of the tungsten wire can be customized according to the heating power and temperature requirements to optimize the application effect. If necessary, please consult us.