Email:

sales@hypersolidmetal.comWhatsapp:

8618625975081

Email:

sales@hypersolidmetal.comWhatsapp:

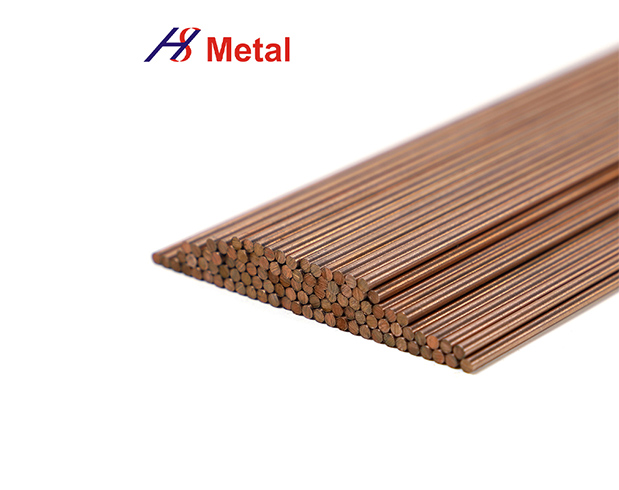

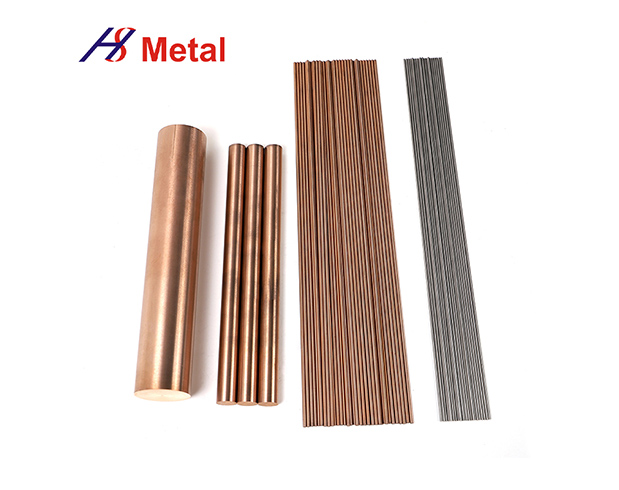

8618625975081As a high-precision non-traditional processing technology, electrical discharge machining (EDM) is widely used to process high-hardness metals and parts with complex geometric structures. In the EDM process, the performance of the electrode material directly affects the processing efficiency, precision and surface quality. Tungsten copper alloy (W-Cu) has become one of the preferred EDM electrode materials due to its excellent electrical conductivity, thermal conductivity and ablation resistance.

1. Working principle and material requirements of EDM electrodes

Electrodischarge machining gradually removes materials through high-frequency pulse discharge between the electrode and the workpiece. It is particularly suitable for materials that are difficult to handle with traditional mechanical processing, such as hardened steel, high-speed steel, and cemented carbide. In the harsh environment of high-temperature arcs and frequent discharges, the electrode must meet the following key requirements:

Excellent electrical conductivity: ensure efficient and stable discharge performance.

High thermal conductivity: rapid heat dissipation, reduce electrode temperature rise, and reduce thermal deformation.

High temperature resistance and thermal shock resistance: resist arc ablation and extend service life.

Low discharge loss: reduce electrode wear and maintain processing accuracy.

Good processability and stability: facilitate the manufacture of complex-shaped electrodes and maintain dimensional accuracy.

With its unique composite properties, tungsten-copper electrodes perfectly match these requirements and become ideal electrode materials for EDM.

2. The core advantages of tungsten copper alloy in EDM electrodes

Low loss and high precision:

The high melting point and high hardness of tungsten make it difficult to melt or wear during the discharge process, which can effectively maintain the geometric profile of the electrode and ensure the high dimensional accuracy and clear edges of the workpiece.

Excellent electrical conductivity and heat dissipation performance:

The high electrical conductivity and thermal conductivity of copper significantly improve the discharge efficiency, reduce the electrode temperature, reduce thermal cracks and surface defects, thereby extending the electrode life and improving processing stability.

Flexible processing adaptability:

Tungsten copper alloy is easy to process, form and surface treat by CNC, suitable for manufacturing electrodes with complex shapes and fine structures, and meet diverse process requirements.

Excellent surface processing quality:

Tungsten copper electrodes have uniform spark distribution during the discharge process, low surface roughness, and reduced subsequent polishing workload, which is particularly suitable for high-precision mold and part manufacturing.

3. Typical applications of tungsten copper electrodes

Tungsten copper electrodes show excellent performance in many high-demand fields.

Plastic injection molds:

Used for processing fine textures, mirror cavities and complex cooling water channels to meet high finish and precision requirements.

Carbide finishing:

Suitable for precision molding of automotive stamping molds, powder metallurgy molds and cutting tools.

Micro-electronic parts:

Such as connector pins, microporous structures and other micro-level discharge machining.

Aerospace and military parts:

Processing complex structures of high-difficulty materials such as high-temperature alloys and titanium alloys.

If you need more information about tungsten copper alloy electrodes or have purchasing needs, please feel free to contact us!