Email:

sales@hypersolidmetal.comWhatsapp:

8615038522042

Email:

sales@hypersolidmetal.comWhatsapp:

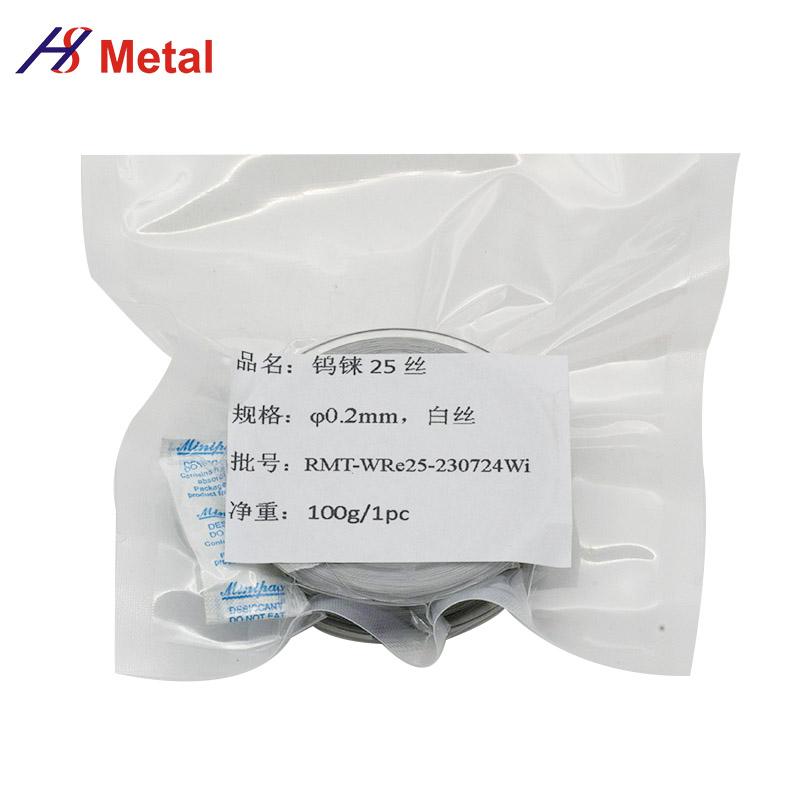

8615038522042Tungsten-rhenium filament is a high-performance alloy wire made by adding a small amount of rhenium to tungsten. It perfectly inherits the high melting point and high strength of tungsten, and achieves revolutionary improvements due to the “rhenium effect”: it does not become brittle after recrystallization, has higher high-temperature strength, and a longer lifespan. This makes it a key material for extreme environments, primarily used in the following high-end fields:

1. The “Heart” of Electrovacuum and Electric Light Source Devices

This is the most classic application area for tungsten-rhenium filament. In high-temperature vacuum environments, pure tungsten filament is prone to brittleness and has a short lifespan, while tungsten-rhenium filament exhibits irreplaceable advantages:

Filaments and Cathodes: Widely used in high-reliability electron tubes, high-power magnetrons (such as microwave oven cores), X-ray tubes, etc. Its anti-sagging and shock-resistant properties can withstand the thermal shock of repeated power-on and power-off cycles, greatly extending the lifespan of the device.

Special Light Sources: Used in cinema projection lamps, searchlights, etc., it can operate stably at higher temperatures, providing brighter and whiter light.

2. A “Scale” and “Heat Source” in Ultra-High Temperature Environments

Thermocouples (Temperature Measurement): Tungsten-rhenium thermocouples are the preferred tool for measuring ultra-high temperatures of 1600℃ to 2300℃, widely used in extreme conditions such as vacuum sintering furnaces, molten steel temperature measurement, and aero-engine testing.

Heating Elements: In high-temperature furnaces protected by vacuum or inert atmospheres, tungsten-rhenium wire is the core material for manufacturing heaters, used in sintering refractory metals, growing sapphire single crystals, and manufacturing hard alloys.

3. Key Components in High-End Manufacturing and Scientific Research

As the cathode of electron beam welding machines and evaporation coating machines, it is valuable due to its stable electron emission performance, high temperature resistance, and long lifespan.

In the aerospace field, it is used as a key component and high-temperature structural part in electric propulsion systems (ion thrusters).

In summary, tungsten-rhenium wire, with its superior high-temperature strength, creep resistance, and ductility, plays an irreplaceable role in cutting-edge technology fields with extreme requirements for reliability, stability, and lifespan.