Email:

sales@hypersolidmetal.comWhatsapp:

8615038522042

Email:

sales@hypersolidmetal.comWhatsapp:

8615038522042The growth of sapphire crystals needs to be carried out in an environment with relatively high temperature and cleanliness. Molybdenum sheets, due to their unique physical and chemical properties, have become an indispensable key material in sapphire crystal growth furnaces.

Molybdenum sheets are mainly used in sapphire growth furnaces for three core functions: structural support, thermal management, and corrosion resistance. Their application runs through the key parts of the furnace:

Molybdenum sheets are used as crucible support and structural components to ensure the stability of the crucible during crystal growth. Specifically, molybdenum sheets are processed into round trays of a certain thickness to carry the weight of crucibles of tens to hundreds of kilograms and withstand gravity loads at high temperatures to avoid deformation. Brackets made of molybdenum sheets are used to fix moving parts such as crucible lifting systems and seed crystal rods, and need to maintain dimensional accuracy at high temperatures.

Molybdenum sheets are used as components for thermal field regulation and insulation, which is conducive to the control of temperature distribution in the furnace, thereby ensuring uniform growth of sapphire crystals. Molybdenum sheets are processed into multi-layer cylindrical heat insulation screens of a certain thickness, surrounding the periphery of the crucible, and reducing heat loss by reflecting thermal radiation. A molybdenum sheet baffle is set above the crucible to adjust the heat flow distribution on the melt surface and inhibit the contamination of seed crystals by volatiles such as Al₂O₃ vapor. Molybdenum sheets with holes or stepped structures are set at different heights of the furnace body to accurately control the temperature gradient of the solid-liquid interface by changing the heat conduction path.

Molybdenum sheets are used as corrosion-resistant and oxidation-resistant components to avoid contamination of sapphire melt. The guide tube made of molybdenum sheets guides the flow of inert gas to prevent oxygen from entering the furnace chamber and causing crucible oxidation. A molybdenum sheet collection plate is set on the top or side of the furnace body to capture Al2O3 particles volatilized from the melt to prevent them from condensing on the furnace wall or seed crystal to form an impurity source.

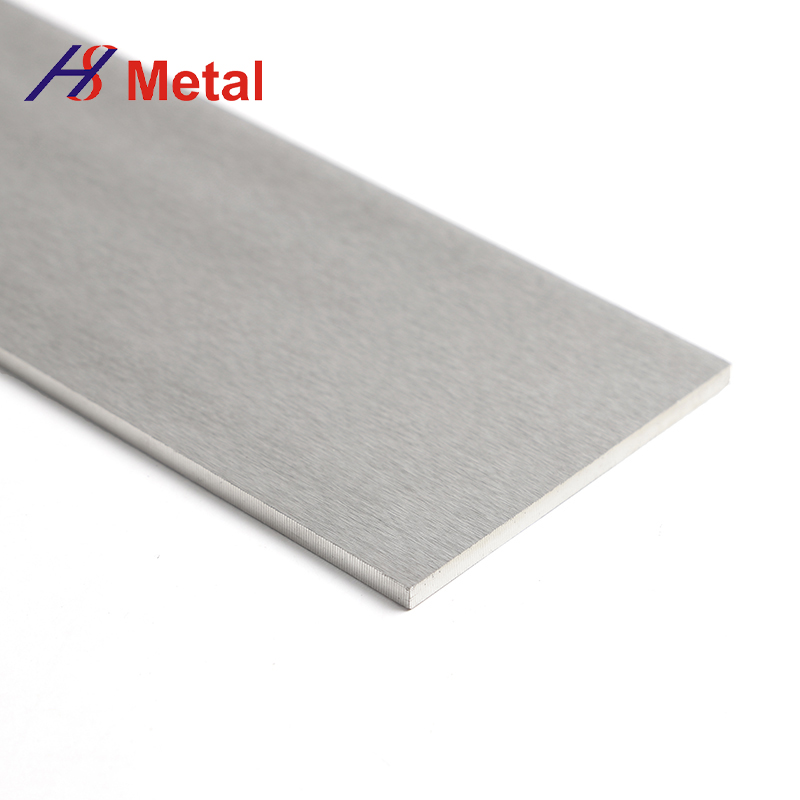

Molybdenum sheets used in sapphire growth furnaces are usually high-purity (purity ≥ 99.95%), and impurities (such as Fe, Cu, Si ≤ 10ppm) must be strictly controlled to avoid contamination of the melt. For example, Fe impurities will form color centers when entering the sapphire crystal, affecting optical uniformity.